What Industries Need 3D Printing Service

3D printing technology has revolutionized manufacturing and production across industries. Also known as additive manufacturing, it builds objects layer by layer using materials like metals, polymers, ceramics, and even living cells. Compared to traditional subtractive methods, 3D printing minimizes waste, enables complex geometries, and accelerates innovation. Its applications span aerospace, healthcare, automotive, consumer products, construction, education, defense, and more. 3D model printing services provide vital capabilities that are driving the digital transformation of these sectors.

Aerospace and Aviation

In aerospace and aviation, 3D printing helps produce lighter, stronger, and more efficient aircraft components. Turbine blades, fuel nozzles, brackets, and interior cabin parts are now commonly manufactured additively. The technology is used to optimize airflow and cooling, consolidate components, customize interiors, and enable periodic inspections. Leading companies like GE and Rolls Royce rely on 3D printing services for next-generation engine and aircraft designs that maximize performance.

Healthcare and Medical

3D printing is advancing healthcare in medical devices, drug fabrication, and diagnostic tools. It enables patient-specific modeling and customization for prosthetics, orthotics, surgical implants, and anatomical models. Such personalized devices fit better, last longer, and lead to improved clinical outcomes. Pharmaceutical researchers use Selective laser sintering (SLS) to design more effective drugs. Additive biofabrication methods even build living tissue constructs for regenerative medicine. By partnering with specialized medical 3D printing services, healthcare providers gain access to innovative capabilities.

Automotive Industry

Automotive companies leverage 3D printing for rapid prototyping and producing lightweight components. The design freedom it provides assists with form optimization for efficiency and styling. Automotive parts like air ducts, housings, and heat exchangers are printed to high standards for quality assurance. Additive methods also enable support consolidation and part count reductions through design innovations. Automakers work with specialized automotive 3D printing services to fast-track development and integrate emerging applications.

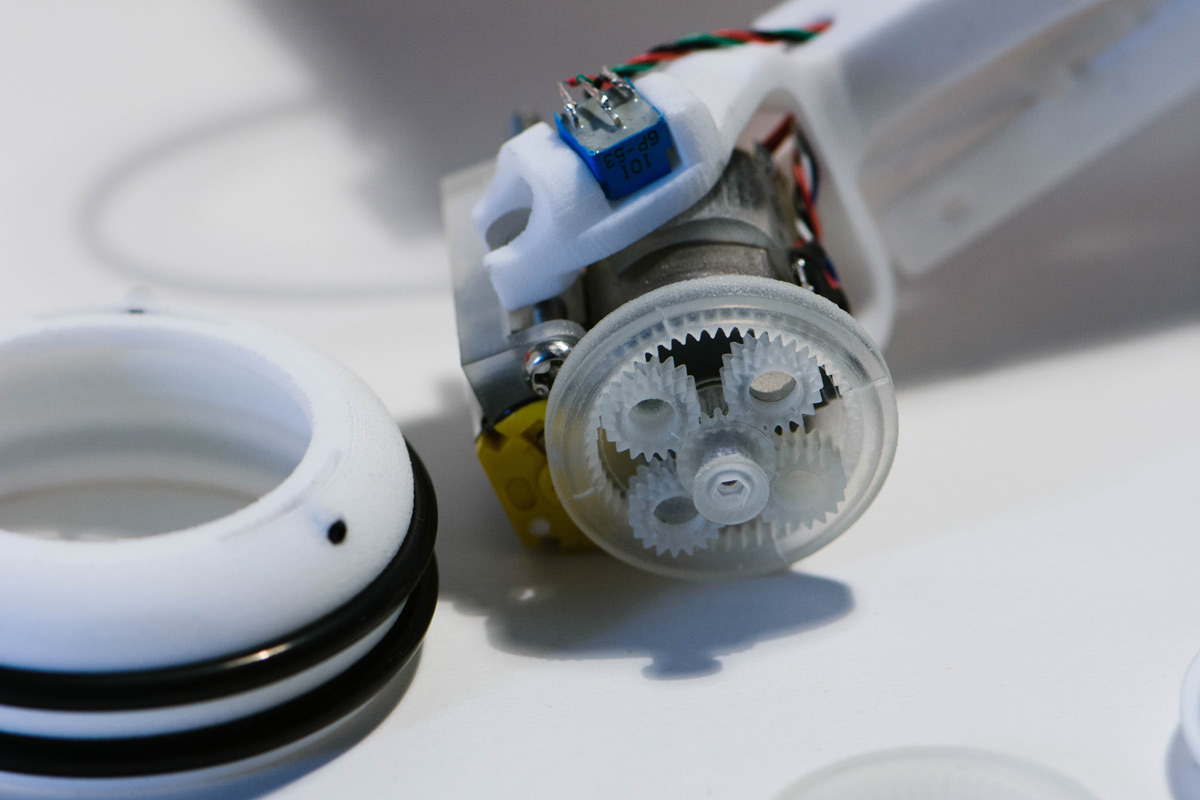

Consumer Products and Electronics

In consumer products and electronics, 3D printing enables mass customization aligned with trends and preferences. It accelerates design iterations and market responsiveness. Electronics companies use additive methods to prototype circuit boards, enclosures, and internal structures with design complexities that are difficult to achieve otherwise. For consumer products, Stereolithography (SLA) 3D printing facilitates creativity for goods like jewelry, toys, sporting equipment, and homewares. It provides design agencies and brands access to an agile production method through on-demand 3D printing services.

Construction and Architecture

Additive construction employs 3D printing for architectural models, building components, and even entire structures. It brings advantages like minimized material usage, consolidated parts, accelerated assembly, and design freedom. Walls, foundations, and floor slabs can be printed from materials like concrete, steel, or composites and snapped together on-site. Specialized equipment extrudes construction material in precise locations based on a digital model. Partnering with 3D construction printing services helps architects and contractors reduce waste and construction schedules.

Education and Research

3D printing technology provides powerful learning and research capabilities. Students use desktop 3D printers to understand principles applied in professional additive manufacturing. Researchers prototype experimental apparatus with complex geometries that are impossible to achieve otherwise. Educators create 3D models of anatomical, molecular, and cosmological structures for enriched visualization. With classroom-ready printer materials and out-of-the-box systems, 3D printing services empower impactful STEM education. University labs also rely on service bureaus to fabricate research instruments using professional-grade polymer and metal printers.

Defense and Military

Additive manufacturing assists defense technology and supports military readiness for ground, air, and sea applications. It helps fabricate components for communications equipment, protective gear, and weapon systems. Land vehicles benefit from 3D-printed parts like air ducts, shock absorbers, and insulation panels. Lightweight printed parts also assist soldier mobility and transportability. For naval vessels, metal 3D printing produces specialized fluid handling parts that are resistant to corrosion. Aerospace innovators develop next-generation missiles, drones, and supersonic aircraft with printed structures. By partnering with regulated 3D printing services, defense agencies gain rapid and secure manufacturing capabilities.

The exponential advancement and integration of 3D printing signals a paradigm shift in manufacturing possibilities. As the technology continues to expand across industries, its future impact promises to be even more transformative. Companies that leverage professional 3D printing services position themselves competitively for the new wave of digital manufacturing. With additive methods proving their industrial viability daily, their revolutionary disruption of production is only just beginning.