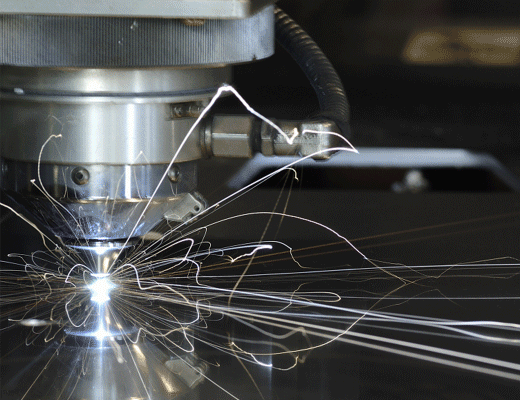

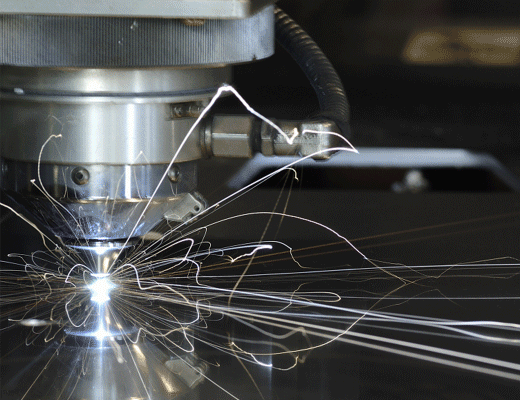

Sheet Metal Fabrication Services

A quick and affordable solution is provided by the custom sheet metal fabrication service provided by QSY for your enclosures, brackets, assemblies, weldments, cabinets, housings, and other sheet metal components and prototypes.

For both prototyping and low-volume manufacturing, our sheet metal prototyping service offers bending, welding, and cutting of standard gauge metal (MOQ is 1). A variety of materials and finishes are available, all suitable for your next project.

Advantages Of Sheet Metal

Used For

Prototypes and low volume production, medical and communications products, housings and enclosures

Advantages Of Sheet Metal

Durability

Material Selection

Rapid Turnaround

Scalability

Custom Finishes

Applications of Sheet Metal

Enclosures

Due to its wide range of industrial applications and its cost efficiency vs. other methods, sheet metal can be used to manufacture a broad range of enclosure features such as rack mounts, distinct shapes and consoles.

Chassis

Sheet metal fabrication has a wide range of applications in the production of chassis from small devices to large testing equipment, because of its hole alignment specs.

Brackets

Brackets produced using sheet metal fabrication are common in various industrial applications as they offer excellent corrosion resistance. All necessary hardware and fasteners included.

Sheet Metal Materials

What is Sheet Metal?

TECHNOLOGY OVERVIEW

Sheet metal is a common form of raw metal stock, usually 0.006 and 0.25 inches thick. Fabrication is a collection of processes used to shape raw metal stock into a usable product. Sheet metal fabrication includes many machining processes meant to assemble, cut, or form a sheet metal workpiece. After fabrication, a product often needs to undergo finishing processes before it’s suitable for commercial use.

FAQ's

The prototypes arrived this morning and they look great. Thank you very much for your work on this project and your prompt and thorough communication. We will certainly be in contact again in the future.

—— Gareth Lauchlan, BDes ID

I would Like to congratulate you and your company with your service and prototyping quality. The communication with our company was very clear and constructive. The prototypes have a very good quality and the delivery speed are fantastic. With your prototypes we can communicate better and faster with our clients and give them a glance of how the product will look and feel Like.Ing. Marc E.J. Van Strydonck Industrial designer.

—— Marc E.J. Van

I do appreciate the time and effort you have put forth and I would love to do business with you in the future. I’ll keep you posted very soon. Thanks aaain, For now we are very happy with the quality of these products, they looked very good and were very well packaged.I do appreciate the time and effort you have put forth and I would love to do business with you in the future. I’ll keep you posted very soon. Thanks aaain, For now we are very happy with the quality of these products, they looked very good and were very well packaged.

—— Roy Navi & Technical Manager

The last tooling you made for us great. I will be sending you more similar tooling for us to order.

—— John Norlin & Technical Engineer

The parts look great! I am especially amazed with the quality of the stainless steel parts, they look awesome and the tolerances are perfect! I might get back to you in four to five months once we will hopefully go into small series production!

—— Andreas Brehm Ph.D., eMBA

Let's Get Started